Granular vs Prilled Urea: A Procurement-Level Comparison for Bulk Buyers

Urea is often treated as a pure commodity. One molecule. One nitrogen percentage. One line item on a purchase order. The assumption follows naturally: if the chemistry is the same, the product must be interchangeable. In practice, that assumption quietly erodes margins.

For bulk buyers, importers, and distributors, the difference between

granular and prilled urea is not cosmetic. It shows up later during discharge at port, inside warehouses, in customer complaints, and sometimes in rejected consignments. Handling losses accumulates. Storage behavior surprises. Downstream buyers react.

In this blog, we will compare prill urea and granular urea. The purpose is not to explain agricultural performance, crop response, or yield. Rather, this is a commercial and operational examination where we will compare both from a procurement perspective. Our focus will be on how the material behaves under pressure, how it travels across borders, and how expectations shift once the product leaves your control. Let’s begin.

Understanding the Physical Difference: Granular vs Prilled Urea

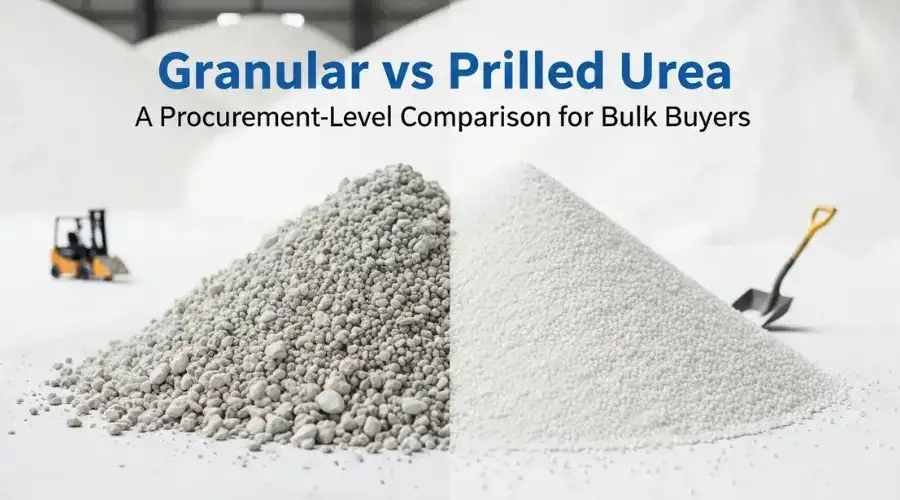

Granular urea is manufactured through granulation processes that produce larger, denser, and mechanically stronger particles. The size distribution is tighter, and the shape is more uniform. The product feels heavier in the hand and behaves that way in motion.

Prilled urea is formed in prilling towers, where molten urea droplets fall and solidify mid-air. The result is smaller, lighter particles with lower crush strength. Visually similar, chemically identical, but the impact and behavior are different on application.

Particle size and hardness matter well beyond appearance. They are a feature that determines how the product resists abrasion, how it tolerates repeated handling, and how much dust forms when energy is introduced during conveying, loading, unloading, or bagging.

A common misconception persists: same nitrogen content means same commercial performance. That belief dissolves quickly once logistics, storage, and resale are factored in.

Handling and Transportation Efficiency

Every transfer point introduces stress. From bulk vessel to hopper. From conveyor to bag. From truck to warehouse floor. Prilled urea, with its lower hardness, fractures more easily under these conditions. Breakage of urea produces fines, which become dust. Dust becomes lost.

Granular urea resists this chain reaction. Its higher crush strength reduces fragmentation during loading and unloading. So dust formation is negligible. Consequently, transit losses also decline.

The longer the distance, the more obvious the differences between the prilled and granulated become. This difference compounds over distance. In long-haul international trade, especially bulk shipping and break-bulk cargo, granular urea consistently performs better. Less degradation across ocean crossings. Cleaner discharge at destination ports. Fewer surprises during customs inspection and inland movement.

On a large scale, handling losses is not theoretical. Even fractional percentage differences translate into material cost. Lost tons. Extra cleanup. Adjusted invoices. Procurement decisions echo through the logistics ledger.

Storage Behavior and Caking Risk

Caking is not an inconvenience but a commercial liability. When urea absorbs moisture, particles fuse. Flowability collapses. What was once free-flowing becomes stubborn and uncooperative.

Granular Urea

Granular urea generally exhibits better resistance to caking, particularly under high humidity and extended storage durations. The larger particle size reduces surface area exposure. The structure holds longer.

Prilled Urea

Prilled urea, especially when stored in port warehouses or coastal climates, is more vulnerable. Long storage times magnify the risk. Bags harden, and a bulk pile forms a crust. Rehandling becomes necessary.

The consequences ripple outward. Inventory turnover slows. Customer complaints increase. Rebagging or reprocessing costs surface unexpectedly. In worst cases, product discounts or write-downs follow.

Procurement insight sharpens here. A lower purchase price loses its appeal when downstream costs quietly inflate. Storage behavior is not neutral. It either protects the margin or erodes it.

Application Compatibility vs Buyer Expectations

|

Dimension

|

Granular Urea

|

Prilled Urea

|

|

Typical Buyer Expectation

|

Viewed as robust, modern, and logistics-friendly. Buyers expect consistency, minimal fines, and trouble-free handling rather than legacy familiarity. |

Viewed as familiar and “traditional” in certain regions. Buyers often expect it because they have always used it, not because it performs better. |

|

Compatibility With Application Equipment

|

Performs best with modern spreaders and bulk application systems designed for uniform particle size. Can create resistance in older or poorly calibrated equipment. |

Better suited to older spreading systems and equipment calibrated for smaller particles. Integrates smoothly where modernization has lagged. |

|

Blending Behavior

|

Uniform size improves blend stability but requires compatible blend ratios and machinery. Poor fit can expose procurement misalignment quickly. |

Smaller particle size can blend more easily with fine materials, reinforcing its appeal in legacy blending operations. |

|

Risk of Buyer Pushback

|

Pushback occurs when downstream users are not prepared for particle size differences. Not a quality failure, but a familiarity gap that triggers resistance. |

Lower risk of initial pushback in traditional markets. Acceptance is often automatic, even when performance limitations exist. |

|

Regional Market Norms

|

Increasingly preferred in export-driven and efficiency-focused markets where logistics and storage discipline matter. |

Still demanded in regions where equipment, training, and habits have not evolved. Market inertia sustains demand. |

|

Procurement Implication

|

Requires active market education and alignment with customer capability. When aligned, complaints drop and operational confidence rises. |

Requires careful monitoring of handling and storage expectations. Familiarity reduces complaints, but masks downstream inefficiencies. |

Cost Structure: Price Per Ton vs Total Cost of Ownership

Granular urea is typically priced a bit higher than prilled urea. The difference is not a lot, but enough to tempt cost-focused procurement teams toward the cheaper option.

But too many sourcing professionals focus solely on pricing and make the wrong decision by failing to consider other costs. They fail to account for transit losses due to dusting. Storage degradation from caking. And customer returns or enforced discounting when performance disappoints.

These costs do not announce themselves upfront. They surface gradually, embedded in operational friction. Each incident seems minor. Collectively, they reshape profitability.

Total cost of ownership reframes the decision and reveals the true value of the urea stock. It accounts for what happens after the invoice is paid. How much product actually reaches the customer and in what condition?

Procurement-level ROI is not about saving per ton. It is about protecting value across the entire chain. Sometimes the higher-priced option quietly delivers the higher return.

Suitability for Bulk Buyers, Importers, and Distributors

Bulk importers operating long international routes tend to favor granular urea. Volume is high. Transit is long. Risk tolerance is low. Mechanical strength and predictable handling outweigh marginal price differences.

Regional distributors operate closer to end markets. Storage durations vary. Customer equipment diversity complicates decisions. Some prioritize granular for stability. Others retain prilled lines to meet entrenched demand. Flexibility becomes the differentiator.

Government and institutional buyers often focus on uniformity, compliance, and large-scale distribution programs. Risk aversion dominates. Granular urea’s handling and storage advantages align well with these priorities, even when procurement cycles emphasize competitive bidding.

Each segment carries different pressures. Volume, storage capacity, market expectations, and political scrutiny all influence the optimal choice. There is no universal answer. There is only strategic fit.

Quality Specifications Buyers Should Verify

Quality control is not optional. Nitrogen content remains foundational, but it is not sufficient on its own. Moisture levels directly influence caking behavior. Biuret content affects acceptability in sensitive markets. Particle size distribution determines handling and application performance.

These parameters carry different weights depending on whether granular or prilled urea is sourced. Granular products demand tighter size consistency. Prilled products require closer scrutiny of moisture and fines.

Supplier documentation matters. So does third-party inspection. Certificates without verification invite risk. Specifications are the contract between expectation and reality. Weak specifications weaken leverage when issues arise.

Making the Right Procurement Decision: A Practical Framework

Identify the target market and resale channel. Long-distance bulk movement favors durability. Short-haul regional sales may prioritize compatibility.

Evaluate transportation distance and mode. Sea freight punishes fragile material. Storage duration matters. Weeks behave differently from months. Customer application requirements cannot be assumed; they must be confirmed.

Finally, assess risk tolerance against price sensitivity. Some organizations can absorb variability. Others cannot. Procurement strategy emerges from these answers, not from habit.

When decisions align with logistics, storage, and customer reality, the result is a seamless process and a higher margin.

Conclusion: Choosing Based on Strategy, Not Assumptions

Granular versus prilled urea is not a technical footnote. It is a strategic procurement decision. One that shapes logistics performance, storage stability, and buyer satisfaction.

Price-only comparisons oversimplify a complex reality. The real cost unfolds after delivery. After handling. After storage. After resale.

Bulk buyers who align sourcing decisions with operational realities outperform those who default to assumptions. Strategy replaces guesswork. Risk becomes managed, not endured. That is where disciplined procurement quietly wins.

FAQs

1. Which urea type is safer for long-distance bulk imports?

Granular urea travels better. It breaks less. It makes less dust. After weeks at sea and rough handling at port, more of it stays sellable. For importers, that matters more than a small price gap.

2. Why do some distributors still insist on prilled urea?

Habit and equipment. Many buyers use older spreaders built for smaller particles. Prilled urea fits without adjustment. It is familiar. Familiar feels safe, even when storage losses say otherwise.

3. Is the cheaper urea really cheaper for bulk buyers?

Not always. Dust is lost. Caking is costly. Complaints turn into discounts. What looks cheap on paper can quietly drain margins after delivery.

4. What should procurement teams check before choosing between the two?

Distance first. Storage time next. Then the customer’s equipment. Price comes last. When these align, the decision holds. When they don’t, problems arrive later.